If you do not have the proper tools, hunting can be ineffective. Many experienced hunters are well aware that carbon arrows play an important role in shooting. That is why, in addition to learning how to shoot, most of them will take their time to make their own bows.

Carbon arrows are much lighter to bear than aluminum arrows. Despite this, they can be used in windy conditions and they are barely blown by the wind while shooting.

Arrows can be used in a number of places. Some people like to buy them from a hunting store, while others prefer to make them at home. Tailor-made arrows are ideal because you can customize their length and shape to your taste. A good arrow has a good vane angle, shape, and weight. If you buy one from the shop, you do not get the one with the features you like. Instead, tailoring it gives you the freedom to experiment with it before you find the functionality you like.

Why don’t we begin by learning what carbon arrows are before we learn how to cut them?

What Are Carbon Arrows?

And at the time of our great great grandfathers, arrows were the most commonly used hunting weapons. However, these arrows have progressed over time from being made of wood to being made of aluminum and carbon. Carbon bows, as opposed to aluminum arrows, are lighter and more durable. As a result, when compared to aluminum counterparts, the speed is excellent.

While many people would prefer to buy premade arrows from hunting stores, others would love to make one for themselves. This gives you great control and ability to customize it to fit your needs.

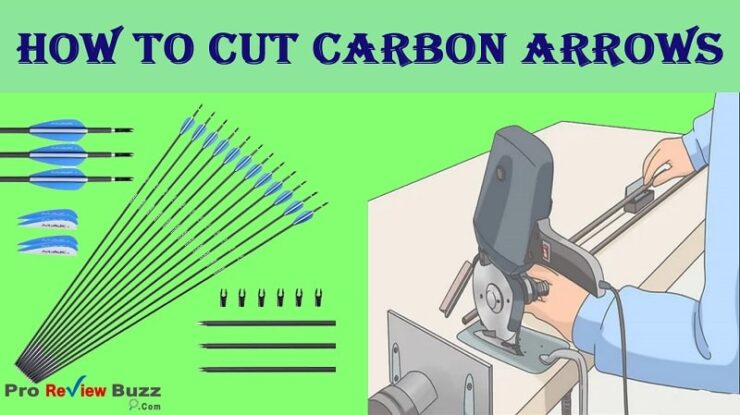

To be able to make one for yourself, you will need to gather some necessary equipment. This includes Carbon Arrows, Cutting tools,masks, gloves, goggles, measuring and masking tape, wooden blocks, sandpaper and finally a mounting tool.

Before you go ahead and begin doing anything. There are a few safety precautions that you need to be well acquainted:

Parts of an Arrow

- Shaft – This is the longest part of the arrow. It can be made of different materials such as aluminium or carbon.

- Arrow- This refers to the tip of the arrow. The very sharp end right at the end.

- The fletching – If you have ever seen some feathers right at the back of the arrow, that is what we call fletching. Its role is solely to keep the balance of the arrow when shooting.

- The nock – Right next to the fletching at the back of the arrow is the nocking point.

Styles of Arrows

Different arrows have different styles. This depends on the purpose that you intend to use it for.The common styles include:

- Bullet points- These kinds of arrows are designed to be slightly sharp and therefore can be used in hunting small animals.

- Field points – Unlike bullet points, these are sharper and they are mostly used in training how to shoot on target.

- Blunt points – These are arrows with flat edge and normally kill the

Process of Cutting carbon arrows

Choosing the Correct Arrow Length.

The first thing you can do is calculate the length of the arrow. It’s no wonder that various sized arrows appeal to a wide range of people. Depending on the size you choose, place the arrow on the mounting surface or table, measure the desired length with a ruler, and finally mark it with a tape. Marking lets you avoid making the error of unintentionally cutting a point where you did not choose.

Cutting the arrows

There are many ways you can cut your arrows. You can either use a rotary cutter, the wheel or a tile saw. All in all the goal is to cut the arrow no matter the tool you use to cut.

If you are going to be using a rotary cutter, begin with setting up the cutter by laying it near the edge of the table.Once that is done, position the shop vacuum hose at the back of the rotary blade. The reason is because there will be a lot of dust produced and therefore the vacuum will ensure the dust doesn’t spread.It is now time to turn on the machines but not until you wear your safety goggles and face mask.Finally, once your rotary tool is up and running at high speed, gently cut the arrows right at the point you marked.

However, if you have an arrow saw instead, then start by attaching a vacuum hose right at the port behind the arrow saw. But if the saw does not have the port, you can as well put it anywhere so long as it is near the blade. Now wear your safety mask and goggles to prevent dust from reaching your body through your mouth or nose. Next is to support the back of the arrow on the saw with a notch. This prevents it from rolling up and down while cutting. Finally rotate the arrow through the blade of the saw to cut. If you saw blades sharp enough, cutting should be done in a matter of minutes.

CONCLUSION

Carbon arrows unlike aluminium are the best cost effective arrows to go for. Despite having the ability to withstand wind drift, it is flexible enough to be bent into original position in cases where it gets bent when it hits an animal.

While you might buy an arrow from a store, it is still possible to make one for yourself. When you decide to tailor your own, it is important to understand that your arrow will contain three which include the notching point, the arrow, shaft and the fletching.

Depending on whether you are training to hunt, hunting a small game or even doing professional hunting, you can make an arrow with different styles. You can either make a bullet, blunt, or field point arrow.

When it comes to the process of cutting the arrows,first you will need to determine the length of the arrow before embarking on cutting business. There are different tools you can use to cut your arrows. While others prefer to cut with an arrow saw, rotary cutter and tile saw can also be utilized.

This article is therefore helpful in informing you on how you can cut your arrow appropriately. With the content we have compiled we sure hope that now you are enlightened on how you can perfectly cut your carbon arrows.